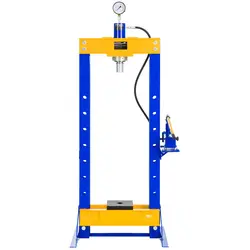

Gjenstand: EX20060301

|Modell: MSW-WP-30T

B-varer Hydraulisk verkstedspresse - Opptil 30 tonn trykk

Våre B-varer er som regel returvarer fra kunder eller tidligere utstillingsvarer. Produktene kan ha kosmetiske feil, men er teknisk sett feilfrie. Som vanlig gir vi normal returrett og garanti.

kr 8 247,61

kr 9 673,30

Leveringsdetaljer

Retur og garanti

Nedlastinger

Tekniske detaljer

Arbeidsområde [mm]

200 - 1200 (9 høydetrinn i intervaller på 125 mm)

Borddimensjoner [mm]

Bredde: 460

Diameter, pressekolbe

160 mm

Maks trykk

666 Bar

Maks. press

30000 kg

Mål (LxBxH)

64 x 73 x 186 cm

Vekt

116.5 kg

Leveringsdimensjoner (LxBxH)

164 x 29 x 38 cm

Fraktvekt

139.5 kg

Produktbeskrivelse

Whether you wish to bend or press metals, or remove gears, washers and threaded bushings, the MSW WP-30T Hydraulic Workshop Press achieves this with ease. The hydraulic press with an integrated manometer has a maximum pressing pressure of 30 T and is perfectly suited for use in the car workshops or within any mechanical engineering operation.

The hydraulic press WP-30 T provides a comfortable work area with a width of 460 mm. The adjustable height (7 different levels) can be adjusted simply, with the help of two pins in a range of 70-1.070 mm. In this way, the press can be comfortably used by persons of different body size.

Metals of various types can be bent and straightened with the aid of the hydraulically compressible pressing pressure of 30,000 kg. The pressure can be precisely determined by the built-in manometer and adjusted by the hand pump. Thus, by a gradual increase in the pressure, a precise pressing result can be achieved. The fully welded construction is very sturdy and ensures a long service life.

The stroke of the press piston is 160 mm, so that the pressure can be collected optimally at the processing point. Both the work tool and the pressure piston are shock-absorbed to absorb vibrations. After completion of the pressing operation, the piston is brought back into the initial position by an automatic retraction function and is ready for the next working operation.

Om varemerket

Vurderinger og anmeldelser

Vurderinger og anmeldelser

Sorter etter :

ANBEFALT AV EKSPERER

17 års erfaring

innen profesjonelt utstyr

3 MILLIONER...

glade og tilfredse kunder