B-varer

Gjenstand: EX20020210

|Modell: S-PLASMA 40

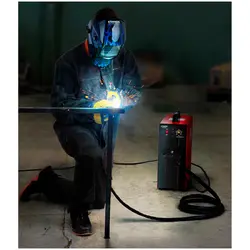

B-varer Plasma Cutter - 40 A - 230 V - Inbuilt Pneumatic Air Compressor

Våre B-varer er som regel returvarer fra kunder eller tidligere utstillingsvarer. Produktene kan ha kosmetiske feil, men er teknisk sett feilfrie. Som vanlig gir vi normal returrett og garanti.

kr 4 199,00

kr 5 199,00

Viktige funksjoner

- A high-performance plasma cutter for workshops, garages and metal fabrication facilities

- Cuts conductive materials such as steel, stainless steel, cast iron, copper, nickel or aluminium

- Integrated air compressor: no external compressed air supply necessary

- Precise and distortion-free cuts up to 10 mm thickness

- Overload protection ensures a high degree of safety and immediately turns off the device if necessary.

Leveringsdetaljer

Retur og garanti

Nedlastinger

Tekniske detaljer

Spenning [V]

230

IP beskyttelsesklasse

IPX3

Konstant trykk [bar]

3.5

Luftstrøm [l/min]

200

Driftssyklus for 40 °C [%]

60

Utgangsstrøm [A]

20 - 40

Inngangseffekt [kVA]

5,08

Effektfaktor

0,73

Kuttbredde [mm]

1

Gass etterstrømning [s]

2,5 - 5

Maks. inngangsstrøm [A]

22

Nominell inngangsstrøm [A]

16

CNC

Nei

2T / 4T

Nei

Vannavkjøling

Nei

Innebygd kompressor

Ja

Strømledning

2.2 m

Plasmakabel

4 m

Jordkabel

1.3 m

Maks. skjæredybde

10 mm

Lengde på lufttrykkslange [m]

4

Mål (LxBxH)

42.5 x 20.5 x 54.5 cm

Vekt

23.07 kg

Leveringsdimensjoner (LxBxH)

56 x 35 x 62 cm

Fraktvekt

29.2 kg

Leveringsomfang

- Plasma cutter S PLASMA 40

- Tool bag

- Ground cable with clamp (3 m)

- Hose package with cutting torch (4 m)

- Power cable (1.9 m)

- 3 x ceramic nozzles

- 3 x ceramic rings

- 3 x electrode

- 3 x cutting nozzles

- User manual

Produktbeskrivelse

The plasma cutter S PLASMA 40 from Stamos Germany cuts electrical conductive materials such as steel, stainless steel, cast iron, copper, nickel or aluminium precisely and without deformation and captivates the market through the use of the integrated air compressor. This reliable and experienced technology ensures always a high level of safety within the working environment. This professional device cuts up to 10 mm cutting capacity up to 40 amps and is ideally suited for repair or renovation work in workshops or garages.

The compact and lightweight design allows for an easy and mobile use.

The cutting or separating of the metals takes place by means of a plasma jet (compressed air) rather than by the use of expensive gases such as argon or nitrogen. The infinitely variable adjustability allows precise control of the cutting current. Due to the high temperature and cutting speed, distortion of the material is minimized and a clean straight cut edges is ensured, therefore no post-processing is needed.

A special feature of the S-PLASMA 40 plasma machine is the integrated compressed air compressor. The advantage compared with traditional systems is that no external source of compressed air is needed and thus no additional devices need to be purchased. This professional device is ideal for mobile use and is easy to transport due to the carrying handle

The device is equipped with the modern V-MOSFET inverter technology, which ensures that the current is used optimally and that damage caused by overvoltage is prevented. The knob is used for continuous adjustment of the cutting current in the range of 20 to 40 amps. With the switch, the after-flow time is selected between 2.5 and 5 seconds.

In addition to the plasma cutter S PLASMA 40, you also receive useful and extensive accessories: a hose packet with torch (type :) PT-31 length: 4 m), a ground cable with clamp (length:) 3 m), 3 ceramic nozzles, 3 ceramic rings, 3 electrodes, 3 cutting nozzles, a tool kit and an instruction manual are supplied.

Vurderinger og anmeldelser

Vurderinger og anmeldelser

Sorter etter :

ANBEFALT AV EKSPERER

16 års erfaring

innen profesjonelt utstyr

3 MILLIONER...

glade og tilfredse kunder